Installation Video

- Use QR code app on your smart phone or tablet to access >B< MaxiPro home page.

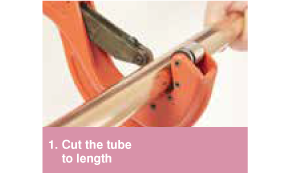

1. Cut the tube to length

- Use a rotary tube cutter.

- Ensure that the tube is cut square.

- Check the pipe has retained its shape and is damage free.

2. Deburr and remove all external sharp edges

- Deburr the tube both internally and externally.

- Where possible angle the tube downwards to prevent filings entering the tube.

- Use a pencil type deburrer on internal tube edges.

- Make sure the internal and external surfaces of the tube ends are smooth and free from burrs or sharp edges.

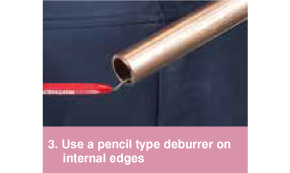

3. Use a pencil type deburrer on internal edges

- Deburr the tube both internally and externally.

- Where possible angle the tube downwards to prevent filings entering the tube.

- Use a pencil type deburrer on internal tube edges.

- Make sure the internal and external surfaces of the tube ends are smooth and free from burrs or sharp edges.

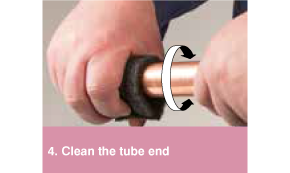

4. Clean the tube end

- Thoroughly clean the tube end using Rothenberger Rovlies or similar cleaning pad in a rotating action.

- Tube ends must be free from scratches, oxidation, dirt and debris.

5. Check for defects

- If deep scratches are still visible, cut the tube back to a clean section.

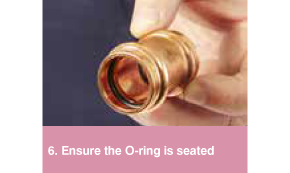

6. Ensure the O-ring is seated

- Check the fitting is the correct size for the tube.

- Check the O-rings are present and correctly seated.

- Additional >B< MaxiPro lubrication may be used to aid tube insertion.

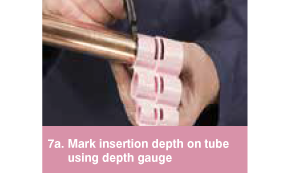

7A. Mark insertion depth on tube using depth gauge

- Insert tube into correct socket in depth gauge.

- Check window to see the tube is fully inserted.

- Mark the insertion depth on the tube.

7B. Alternatively insert tube to tube stop and mark

- The tube must be fully inserted into the fitting until it reaches the tube stop.

- To reduce the risk of dislodging the O-ring rotate the tube (if possible) while slipping it into the fitting.

- Mark the insertion depth on the tube.

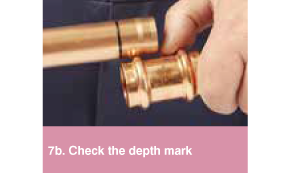

7B. Check the depth mark

- Remove the tube and align with fitting socket, check that the depth mark is correctly positioned.

- The insertion depth mark is used as a reference prior to pressing the joint.

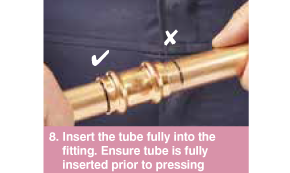

8. Insert the tube fully into the fitting. Ensure tube is fully inserted prior to pressing

- Insert the tube fully into the fitting up to the tube stop.

- To reduce the risk of dislodging the O-ring rotate the tube (if possible) while slipping it into the fitting.

- Prior to pressing ensure the tube has not moved out from the fitting socket.

- Use the insertion depth mark as a guide.

9. Align jaws squarely on the fitting

- Ensure pipework is correctly aligned prior to pressing.

- Ensure the correct size jaw is inserted into the tool.

- The jaws must be placed squarely on the fitting locating the groove on the bead.

- The bead on the fitting should fit centrally in the groove of the jaw.

10. Complete the joint with the approved tool. Press once only

- Depress and hold the button to complete the pressing cycle.

- Pressing is complete when the jaws are fully closed and the piston retracts.

- Complete the press cycle once only – do not repress.

- Release the jaws from the pressing

11. Mark the completed joint

- Mark the completed joint after pressing.

- This enable joints to be inspected easily before testing and insulating the pipework.