Engineering with Copper

Why Is Copper Used in Engineering?

Copper is an indispensable material that is commonly used in engineering thanks to its combination of properties. Second only to silver, its electrical conductivity makes copper the perfect foundation for use in electrical wiring and components which ensures efficient energy transfer.

Copper’s use in engineering goes beyond electricity, as it also has excellent thermal conductivity; this is vital in applications such as heat exchangers, radiators and cooling systems. It also means that the use of copper can reduce overall energy consumption and increased efficiency. Copper is a material which is resistant to corrosion, so offers durability and reliability, particularly when used in harsh environments.

Copper is highly malleable which allows it to be easily formed into complex shapes, across a range of different projects. This highly sustainable and desirable material is suitable for use in a range of diverse sectors.

Copper Engineering Solutions

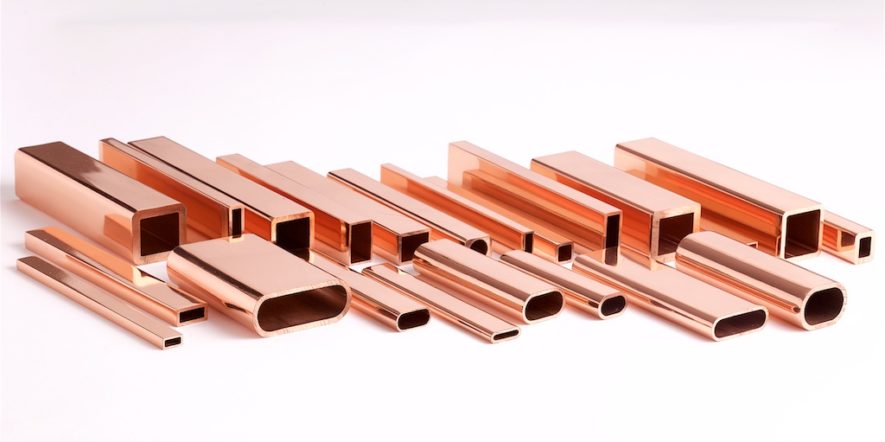

hanks to our production capabilities and our collective skill set, we’re able to offer you a diverse selection of copper engineering products. We specialise in the manufacturing of precision copper and copper-nickel (cupro) tube, with straight cut lengths ranging from 6mm to 10m and copper coils ranging from 5m to 50m.

We’re able to manufacture copper engineering pipes and tubes to the tempers you may require. With surface hardness ranging from between soft to skin hard, we design our copper tubes to withstand sophisticated engineering and bending operations.

Our copper engineering products are produced under our ISO 9001 quality certificate and are Eddy (ECT) current tested. We ensure to hand inspect our products at various stages of production and offer either hand or machine deburring, depending on your requirements. At Lawton Tubes, we pride ourselves on a fast manufacturing turn around, with our products despatched and delivered on our dedicated fleet of vehicles.

Applications and Industries

Thanks to copper’s multifarious range of properties, copper engineering products are used in a number of different industries due to its thermal conductivity, malleability and resistance to corrosion.

The electronics sector is reliant on copper for wiring, cables and circuit boards and is used in everything from consumer electronics to power grids and renewable energy systems. Copper is indispensable in the construction industry and is widely used for plumbing, roofing and HVAC systems thanks to its aesthetic appeal and durability.

Copper is utilised heavily in the transportation industry, particularly in electric vehicles, aircraft and trains, as well as the aerospace and defence sectors. As components used in these industries generate significant heat, copper engineering systems help to dissipate heat effectively.

As a naturally antimicrobial material, copper plays a huge role in the medical industry. Copper can help disrupt bacterial, fungal and viral cells, making it a valuable tool in healthcare settings. Further to this, copper is also used in a number of medical devices and machines, such as MRI machines, lasers and pacemakers, thanks to its electrical conductivity properties.

Lawton’s Copper Engineering Products

Our copper engineering pipes, tubes and products are made to order, with an average manufacturing time of 4 weeks. With our products, we manufacture and distribute following the BS EN 12449, BS EN 12541 and BS EN 13600 European specifications. We also have the capacity to manufacture and distribute copper engineering products following American ASTM specifications.

For more information or to place an order enquiry, please contact our sales department.

In engineering, copper is used primarily for its electrical and thermal conductivity which makes it ideal for use in a number of applications and projects. It has high electrical conductivity, is inexpensive to use and is ductile, so copper lends itself to a number of engineering uses and requirements. It is one of the most universally accepted materials within engineering.

Copper is one of the most sustainable materials available, with a near-100% recyclability that gives no loss of its properties. It is estimated that around 80% of all copper produced in the last 10,000 years is still in use today. In addition, it uses 15% – 40% less energy to recycle copper than to produce it, making its reuse entirely viable. The longevity of copper means it contributes less waste by helping to expand the lifecycle of copper engineering components.

We have strong established relationships with our shipping partners to allow us to deliver our services outside of the UK. Our logistical capabilities mean that we can safely and securely ship copper tubes and pipes anywhere in the world with local distributors in over 35 countries. Throughout the years, we have been able to support the building and fitting out of numerous major international projects, including:

Zayed University, Abu Dhabi

London 2012 Olympic Stadium and Village

Camp Eggers in Afghanistan

The USA Air Force base

Our minimum delivery for UK merchants is 1,000kg of copper tube or pipes for FOC (around £6,000 (ex VAT) in value). For more information and enquiries, please contact our sales team.