Copper is a natural resource that’s found everywhere. Used by humans since the dawn of civilisation, copper is purposed across multiple industries, for numerous applications, in ways most people don’t even think of.

Copper is inside our homes, schools, offices, and hospitals. It’s used in vehicles, appliances, and production processes; it’s a core component used by OEMs the world over; it’s even present in our bodies, essential to its basic functions.

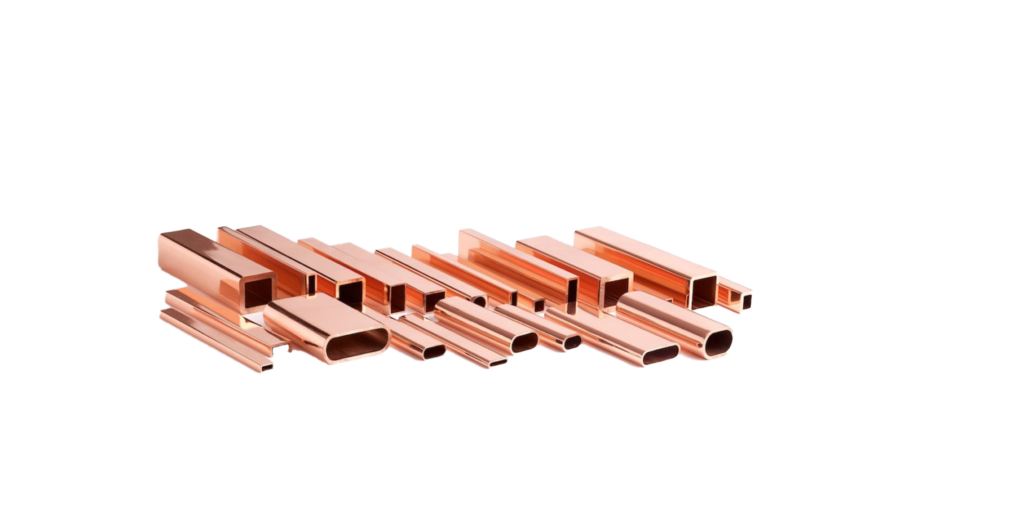

As a cornerstone of British manufacturing, Lawton Engineering is globally recognised for excellence in precision-engineered metal, such as copper, copper nickel, stainless steel, and brass products. Operating three state-of-the-art UK factories, we export our copper tube across the UK and to over 42 countries worldwide.

This is just the start of their incredible journey however: the real story is where our copper products end up. In fact, we at Lawton Tubes play a vital part in the everyday lives of millions of people across the globe, without them even realising it!

Copper in your home

Copper is a crucial component in the running of your home. Found in everything from plumbing and wiring to cooking implements, fixtures, fittings, electricals, and household appliances. Copper is even present in the foods we eat; meat, shellfish, wholegrain cereals, and vegetables like potatoes and mushrooms are all sources of copper – which is just as well; copper supports the healthy function of several major organs including the liver, brain, and heart.

The average home contains around 200kg of copper – that’s the same weight as an adult mountain gorilla! In a single-family home, around 88.5kgs of this can be attributed to wiring; a further 68.5kg comes from the plumbing, tubes, and fittings, just like those manufactured and supplied by Lawton Tubes.

As the UK’s sole manufacturer of copper cylinder fittings, we produce over 8 million annually, and these can be found in households nationwide.

Copper in your community

Copper underpins the infrastructure of towns and cities across the world. At our Poole site, we produce over 2 million 4mm x 307 long copper tubes for heat exchanges which is enough copper to heat up an entire city!

From its use in public buildings such as schools, libraries, and hospitals to its applications within the renewable energy, heating, refrigeration, and telecommunication sectors – copper plays a vital part in the sustained delivery of our public services, supporting essential aspects of our everyday lives many of us take for granted.

In the UK alone, there are 32,149 schools; 1,148 hospitals; and over 2,890 libraries – that’s more than 36,000 facilities, all of which rely on the exceptional properties of copper components to help them provide reliable, ongoing services for their communities.

In 2020 following the pandemic, Lawton Tubes delivered over 120 miles of medical gas pipe to 70 different NHS locations across the UK. From Dundee to Jersey, you’ll find our copper products in the walls, floors, and ceilings of NHS buildings, helping to deliver critical care to those who need it most.

Copper on the move

In addition to the places where you live and work, copper is also found in a whole host of commodities that enhance your everyday life, including transportation.

The automotive industry relies heavily on the use of copper components in the manufacture of all kinds of vehicles, from cars, motorcycles, and buses to HGVs and caravans!

The average modern car has over 1km of copper cable in its sensors, switches, and safety systems, and for powering things like lamps, air conditioning, brakes and electronic comms (ase.org.uk).

Then there are other essential copper components, such as brake pipes and oil coolers, like those manufactured at Lawton’s Poole facility.

An estimated 755,000 touring vans and caravans are regularly in use in the UK. In addition to all the copper cabling these homes-on-wheels contain, they also use copper pipes and fittings for their gas supply – many of which are manufactured and supplied by Lawton!

Some vehicles that are less every day for most people, but essential all the same also use a substantial amount of copper. These include the tanks, aircraft, and sea vessels used by the MOD.

The UK’s military helicopter fleet has a diverse range of aircraft for its various operations: Chinooks for heavy lifting, the Apache for attack, the Puma for support, and the Wildcat for maritime and reconnaissance missions.

Lawton’s precision-engineered copper chopper components, manufactured at our Poole facility, play a crucial role in keeping our forces flying!

Copper: a story without end

Copper’s inherent, unique qualities are the reason it has so many varied uses and applications.

It’s an excellent conductor of heat and electricity; it’s strong and durable yet malleable; it’s resistant to corrosion and has a high melting point. Copper even has its own antimicrobial properties that kill bacteria on contact, making it especially suitable for use in the medical industry.

But copper’s biggest boast is that it is infinitely recyclable. That means it can be re-used again and again without compromising its other properties. It doesn’t weaken or degrade; pure copper is always copper, no matter what form it takes.

At Lawton Tubes, we prioritise the use of recycled copper.

So, whether it’s a domestic fitting on a hot water cylinder in Lewes; a medical grade gas pipe in an ICU in Inverness, or a copper component on a caravan in Carmarthenshire, that’s not necessarily the beginning – or the end – of that copper product’s story.

Who knows? One day it might become part of a Royal Navy helicopter, serving King and country overseas!?

Keep Reading

Continued collaboration with valued customers facilitates NHS hospital development

Proud to Sponsor the CW Awards Global Player Category for 2026