Here at Wardtec, integrity is at the heart of our operations. As a company serving markets with high manufacturer demands, we have consistently demonstrated our ability to meet and exceed those demands. Our comprehensive services cover the entire product development journey, from initial design concepts to prototyping and high-volume production supply.

Wardtec works closely with our overseas suppliers to ensure that all products are manufactured to exact specifications. All factored products undergo rigorous post-production inspection before reaching our facilities at Wardtec.

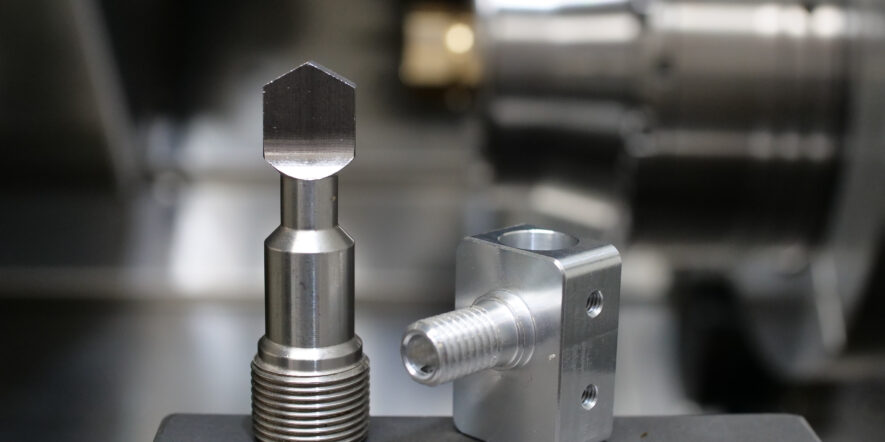

We also offer a bespoke engineering service for customers, working alongside you to design and manufacture a product to your exact requirements.

ISO 9001 Quality Management System (QMS)

At Wardtec, we take quality control and production traceability seriously, adhering to the ISO 9001 standards. Our ISO 9001 certification serves as the cornerstone for ensuring the quality of each manufactured component. Every item is assigned a product card and subject to inspection in accordance with ISO 9001 Key Performance Indicators (KPIs).

Achieving ISO 9001 certification signifies Wardtec’s commitment to delivering products and services that consistently meet customer requirements, showcasing our dedication to excellence.

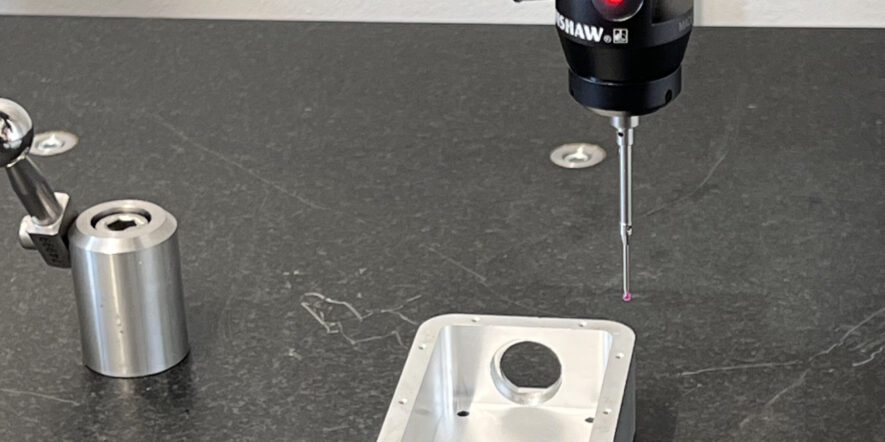

CMM Measurement Service

Wardtec believes in continuous investment in quality control methods, an example of which is Coordinate Measurement Machines (CMMs), capable of measuring any point in a 3-dimensional envelope to within a few microns relative to a datum. These cutting-edge machines empower us to swiftly and accurately assess intricate components, providing detailed computer readouts of all features and measurements.

The speed and accuracy of CMM proves invaluable for Wardtec, enabling seamless integration with modern QA methods like Initial Sample Inspection Reports (ISIR). They not only enhance our internal quality control systems but also prove indispensable in reverse engineering products from customer samples.

By capturing measurement data from physical samples, we can seamlessly integrate it into our CAD (Computer Aided Design) system, creating a 3D virtual model and generating machine programs through our CAM (Computer Aided Manufacturing) software.