At Lawton Tubes, we hold a vast selection of copper and brass pipe fittings in stock. Here’s a look at some of the fittings we carry for copper pipework, with information on the various sizes of fittings available and their applications. Even though there are several options all are covered by the EN1254 standard.

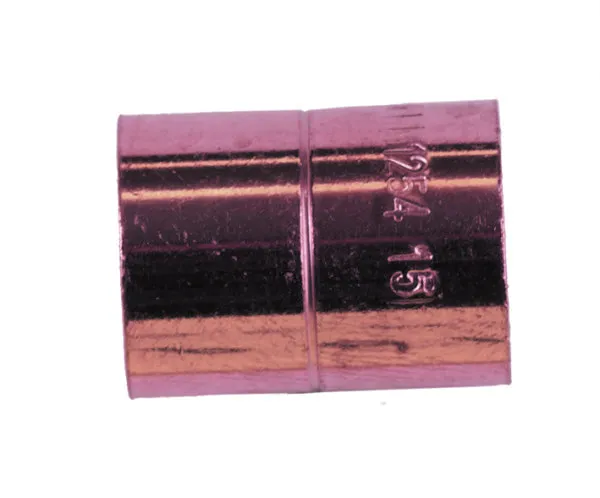

End-Feed / Braze fittings

End-feed / braze fittings are a means of joining two copper pipes together.

Sizes 8mm to 54mm require the use of lead-free solder and a blow torch to permanently marry the two ends of the pipe and create a watertight seal.

Sizes 67mm and above use brazing rods. The main composites are copper and silver. An air-fuel or oxy-fuel torch is required as rods melt at a higher temperature.

End-feed fittings are mostly manufactured from copper (with a few brass ones available as well). They can be used to effectively build one continuous length of copper pipe, which will only come apart again if it’s reheated, damaged, or cut.

End-feed fittings come in a wide range of sizes and shapes depending on the type of join you want to achieve. These include:

- Coupling for joining two copper pipes of the same diameter in a straight line

- 45 and 90-degree elbow fittings

- Reducers for joining copper pipes of different sizes

- Tee for joining up to three copper pipes where they intersect at a T junction

- Crossovers for when you need to run one pipe over another

- Male Adaptors Male Union Adaptors – Just two items in the range of brass fittings

Sizes available

All Lawton’s end-feed fittings are available in sizes 8mm to 54mm and brazing fittings 67mm to 219mm for use with our entire range of copper plumbing pipes, which comply with BS EN 1057. We also offer metric to imperial end-feed fittings such as metric to imperial couplings

Applications

All Lawton’s end-feed / braze fittings comply with EN 1254-1. They are all seamless one-piece fittings, making them more robust and straightforward to use.

Our large selection of quality copper end-feed / braze fittings can fit together everything from domestic copper pipes to large-scale commercial installations.

Our larger 219mm fittings are regularly used in projects such as schools, hospitals, and commercial properties. They can also be used in cold and hot-water plumbing and are the preferred choice for high-pressure systems owing to their superior strength and reliable seal.

Lawton Tubes also carries a selection of soldering products for use with our copper end-feed fittings, including flux, brazing rods and leadfree and leaded solder reels.

Solder ring fittings

Solder ring fittings perform a similar role to end-feed fittings in that they are used in plumbing to join two copper pipes with a permanent seal.

Unlike end-feed fittings, solder fittings do not require the addition of a soldering agent because they come with a ring of solder already built into the fitting.

All that’s required to secure a copper solder ring in place is the heat from a heat lamp to melt the solder already inside the fitting, which then forms a permanent seal joining the two copper pipes.

Solder ring fittings are available in the same varieties as end-feed fittings, including 45 and 90-degree elbow bends, reducers, couplings, tee, and end caps.

Sizes available

Lawton copper solder ring fittings use lead-free solder and are available from 8mm to 54mm. Our solder fittings also comply with EN1254-1 and are suitable for Lawton EN 1057 copper tubes.

Applications

Copper solder ring fittings are a fast, effective solution for joining copper plumbing pipes on various installations where time management is essential.

They can be used in domestic and commercial settings, offering a versatile, reliable solution to soldering pipework in hard-to-reach places. They are also an ideal option for fitters with limited soldering experience, as the integral solder within the fitting requires only a gas torch to give a good seal and makes installation much quicker and simpler.

Compression fittings

Compression fittings consist of the body, the compression nut, and the ‘olive’. They don’t require sealing materials because the olive inside the fitting performs this task.

The end of the copper pipe to be joined is inserted into the body of the fitting. The bevelled olive then slips over the pipe to sit between the pipe wall and the inside of the body, creating a snug fit.

The compression nut then slides over the olive and screws onto the body, tightening the olive around the pipe and forming a watertight seal within the fitting.

Compression fittings come in various shapes and sizes depending on the type of join you want to achieve. Couplings, elbows, tees, crossovers, and reducing are ways to joining copper pipes together using this same compression method.

Blanking discs also work by compression. These can be used to seal or ‘blank’ off the open end of a pipe.

Compression fittings intended for use on copper pipes are usually manufactured from brass.

At Lawton Tubes, we also offer chrome-plated options.

Sizes available

Compression fittings are sized per the diameter of the copper pipe they are to be used on.

All Lawton compression fittings are available from 8mm to 54mm for use with the Lawton range of copper plumbing and heating tubes, which comply with BS EN 1057

Applications

Compression fittings are usually used for low-pressure applications no greater than 125psi.

They are commonly used to join copper pipes in plumbing installations because they are fast, convenient, versatile, and require minimal tooling.

They also offer a good seal, and if the plumbing ever needs upgrading, they are easy to remove and replace.

There are several different types of compression fitting:

- Coupling: allows you to join two copper pipes of the same diameter, end to end, in a straight line

- Elbows: allow you to join two copper pipes at an angle of 45 or 90 degrees

- Tees: allow you to join up to three copper pipes where they intersect at a T junction

- Crossovers: allow you to join up to four copper pipes at a crossover intersection

- Reducings: allow you to join copper pipes of differing diameters, connecting a larger pipe to a smaller one